When you hear the word “machining” you might picture one of those uncool, unglamorous manufacturing jobs that involve endless hours of monotonous tasks. But this couldn’t be further from the truth. In fact, machining is a dynamic industry that offers interesting and challenging opportunities for career-minded individuals who are looking to develop their skills and explore new opportunities.

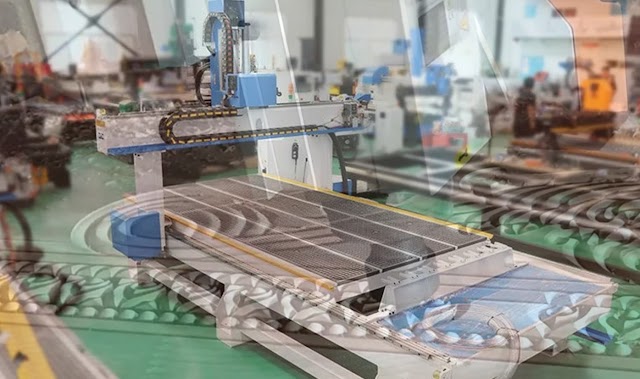

Implementing computer-assisted machine tools in your business has many benefits. It can reduce production time, increase output and reduce waste material at a lower cost than manual methods.

When it comes to machining as an independent business venture, there are many things you need to know before jumping in head first. To help you navigate these unchartered waters, we’ve put together this ultimate guide to machining as an independent business venture – so read on!

What is Machining?

To put it simply, machining is the manufacturing process of creating a part or a component from a raw piece of material by removing portions with a machine tool. Machining is considered to be one of the most important processes in industry because it is used in the making of all manufactured goods – from car components to airplane engines and even surgical equipment. Not all materials are equally easy to machine – so, before you get started, you need to familiarize yourself with the different materials and their machining characteristics.

The Benefits of Machining

When it comes to the benefits of machining, there are many to explore. Perhaps the most notable benefit is the fact that it can be done in most industries. The fact that you can use machining in a wide range of industries makes it more versatile and valuable. Machining is also a highly flexible process because it can be done with both manual and automated machines.

Beyond the core benefits of machining, the following are just a few additional benefits you should know about:

- With machining, you can create products that are accurate, highly durable and precise. You can also create products that are lightweight and can be used in many different environments.

- You can also use machining to create a range of different products. Whether you want to create a few parts or many, you can do this with a machine.

- You can also control the cost and output of your business by controlling the machine. By choosing the right machine for the job, you can save time and money.

The Costs of Starting a Machine Shop

- As with any business, there are costs associated with starting a machine shop. However, at the same time, there are ways to save money and keep costs down – especially if you plan ahead.

- One of the main costs you need to consider is the cost of your equipment. You need to find the right equipment for the job.

- But what is the right equipment? When it comes to the cost of equipment, you need to be realistic when choosing your machines. You don’t need the most sophisticated and expensive equipment. Instead, you need to look for the right balance between quality and price.

- A quality machine with a slightly lower price tag is often a better choice than a cheaper machine. Another cost you need to consider is the cost of your facility. You need to think about the space you need and whether you need to modify the existing space to make it fit for your business.

How to Find the Right Location for Your Business

When it comes to finding the right location for your business, you need to be mindful of a few things. The first thing you need to consider is the cost. You don’t want to overpay for a location just because it is expensive. It is important to find the right balance between price and quality.

If you want to make sure you get the best bang for your buck, you can use a real estate agent. Another option is to do your research online. Once you have a few places in mind, you need to make sure they are a good fit. You want to make sure the location is accessible, has good utilities (electricity, gas, water) and is safe and secure.

Once you have found a few suitable locations, you need to narrow it down to one. When making this decision, you need to think about the location from a business perspective, not a personal one.

You need to ask yourself if this location is the best fit for your business. Is this the right location for your business? Where will your customers be? How will your business be visible? Is it easy to get to? Where will your business be accessible? These questions will help you narrow down your options and choose the best location for your business.

Selecting the Right Type of Machine: Deciding on Tools

Like we said, before you buy a machine, you need to know what you are looking for. This means you need to be familiar with the different types of machine tools and their functions.

Once you know what you want, you can start to look for a machine that fits your needs. You’ll want to make sure the machine has the right balance between quality and price. Once you have the right machine, you can start to consider software. You may want to consider computer-assisted machining (CAM).

CAM software will help you to create and run programs. It is a computer program that is used to generate instructions for a machine tool. These programs allow you to create complex parts with fewer instructions. They also allow you to operate more efficiently. This software can be integrated with your machine, so you can run your machine from a computer program.

Final Words

Machining is a dynamic field that offers interesting and challenging opportunities for career-minded individuals who are looking to develop their skills and explore new opportunities. When it comes to machining as an independent business venture, there are many things you need to know before jumping in head first. To help you navigate these unchartered waters, we’ve put together this ultimate guide to machining as an independent business venture

– so read on! When it comes to the benefits of machining, there are many to explore. Perhaps the most notable benefit is the fact that it can be done in most industries. The fact that you can use machining in a wide range of industries makes it more versatile and valuable.